This machine is designed to have no cam and without swing arm, which shorten the installation time and labour cost. less skill will be enough for tough task. keeping the advantage of traditional forming machine. excellent servo motors and reducers ensures excellent movement and precision of forming.

CNC642A wire rotating spring forming machine adopts CNC control system made in Taiwan and servo motor imported from japan.

The cam axis, feeding axis five axis quill rotating axis, wire rotation axis and auxiliary axis and five axis are interconnected with running.

Eight-position working continuously, standards five axis. (Servo spinner and second hook station can be added).

It is suitable for making varies compression spring square spring scoll spring tower spring double torsion spring flat spring and such difficult abnormality springs. Greatly enlarge the spring processing range. The machine has tracking detection, if there is sub quality product, the machine will automatically stop.

The feeding systems are equipped horizontally at the rotation system of the machine, two rollers as one group. CNC642A has three group feeding rollers. Different wire size needs different feeding rollers. The computer control the feeding system, the moving unit is 0.01mm, the maximum moving length is 99999.99 unit. Adopt the car engine lubricating method inside. The feature: abrasion-proof, minimum noise, high precision synchronism with the control system.

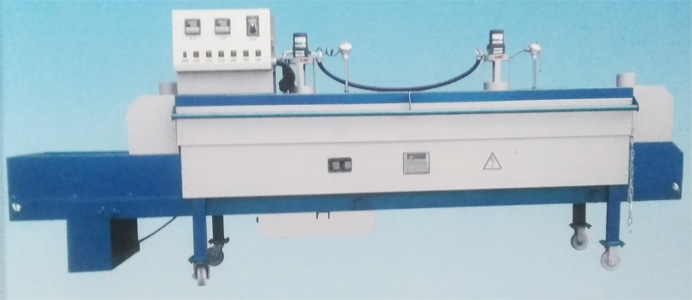

The KU 540/85 Air Circulating Furnace from the KU series has a volume of 540 litres and is suitable for temperatures up to 850°C.

This model is suitable for a variety of materials and applications and is used for tempering, aging, preheating, drying, shrinking, curing and testing for instance. The versatile furnaces can be used for many other materials and applications such as bending, hardening or aging of plastics.

The robust housing construction consists of high-quality steel sheets. The internal housing is made of heat-resistant stainless steel guaranteeing a long service life and is extremely durable and corrosion-resistant. The high-quality insulation ensures efficient use of energy and contributes to reduced electricity costs and low external temperatures.

A spring coiling machine typically operates by feeding wire into a coiling mechanism, where it is then shaped into springs. The materials used in these machines must possess durability and resistance to wear, as they frequently handle high-tensile metals.